Friction Stir Welding & Friction Stir Processing

Revolutionizing Materials Processing

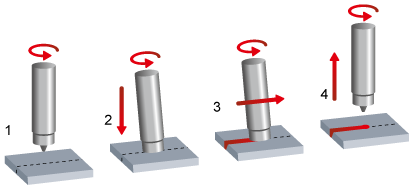

The Process

During the FSW process a rotating, a wear-resistant welding tool generates frictional heat at the welding zone. The material becomes malleable and is stirred along the welding path by the welding tool without reaching the melting temperature of the joining materials. The stirred material is compacted by the tool shoulder and a solid, media and pressure-tight joint between the work pieces is formed.

Unlike conventional fusion welding processes, FSW does not require additional welding wire, inert gas or complex exhaust systems. And, FSW does not generate any discernible noise, smoke or sparks.

The Advantages

- Solid phase joining technology i.e. process temperature is below the melting point of the materials

- Durable media and pressure-tight welding seams

- Joining of aluminium alloys that are not fusion- weldable

- Joining of dissimilar metals

- No formation of hydrogen pores or hot cracking

- Highly reproducible seam strength and seam quality

- Inert gas, powder, welding wire etc. are not required

Interface Design Associates - your trusted partner for advanced FSW solutions.

As an experienced system integrator and supplier of friction stir welding equipment, Interface Design Associates delivers turnkey FSW process solutions to academia, industry and research establishments

Apart from supplying welding machinery and equipment, Interface Design Associates’ integrated approach includes process development for customer applications and FSW tools.

FSW tools are designed and manufactured in house according to specific customer requirements (e.g. welding speed or durability of the tools). This integrated approach ensures that the welding equipment, process parameters and welding tools perfectly match and contribute to the highest joint quality.

Furthermore, at its Technology Center, Interface Design Associates provides assistance starting with test welding, prototyping and small batch contract manufacturing.